What if your spoils were an asset?

Excavated spoils from tunnel, crushed concrete, excavated earth…

Mineral resources are becoming scarce, let us use excavated materials as a source of added value.

From in-situ re-use to most ambitious valorisation avenues, MS is on your side to make these ideas come true.

- Definition of the optimal process

- Preliminary tests in our test centre

- A unique know-how to valorise these materials for construction

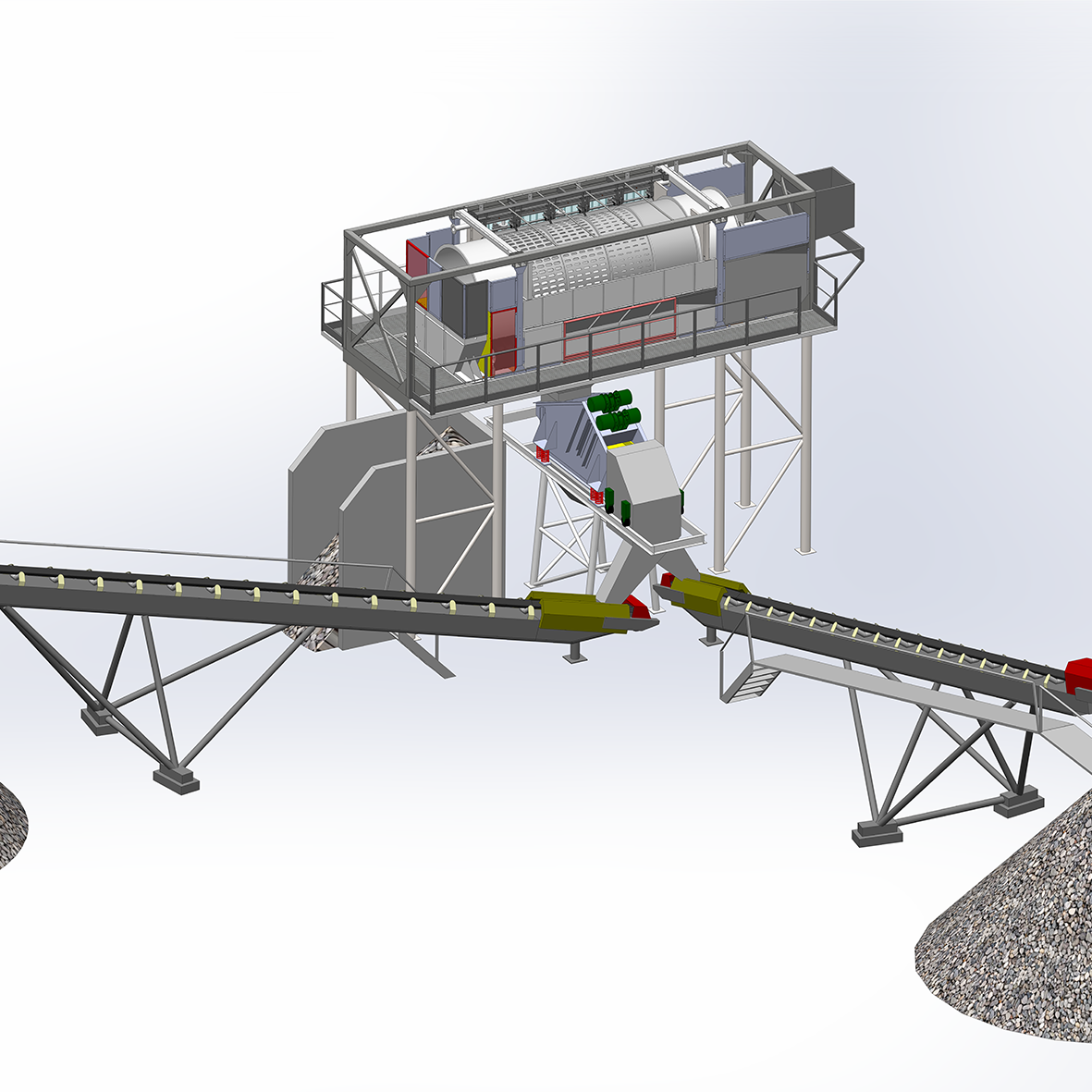

Save Sand on Baho site – Customer : Vaills (France)

Save Sand has been awarded the SOLAR IMPULSE LABEL!

To meet environmental challenges while enabling economic growth, Bertrand Piccard, through the Solar Impulse Foundation, has launched the challenge of selecting 1,000 cost-effective solutions capable of protecting the environment, in order to convince political and economic decision-makers to set more ambitious energy policies and environmental targets, which are necessary to bring these solutions to market on a large scale.

Our solution was chosen to be exhibited at L’Élysée in July 2023! Open to the public, our installation represented our region and the “Made in France” approach needed to bring these solutions to market on a large scale.

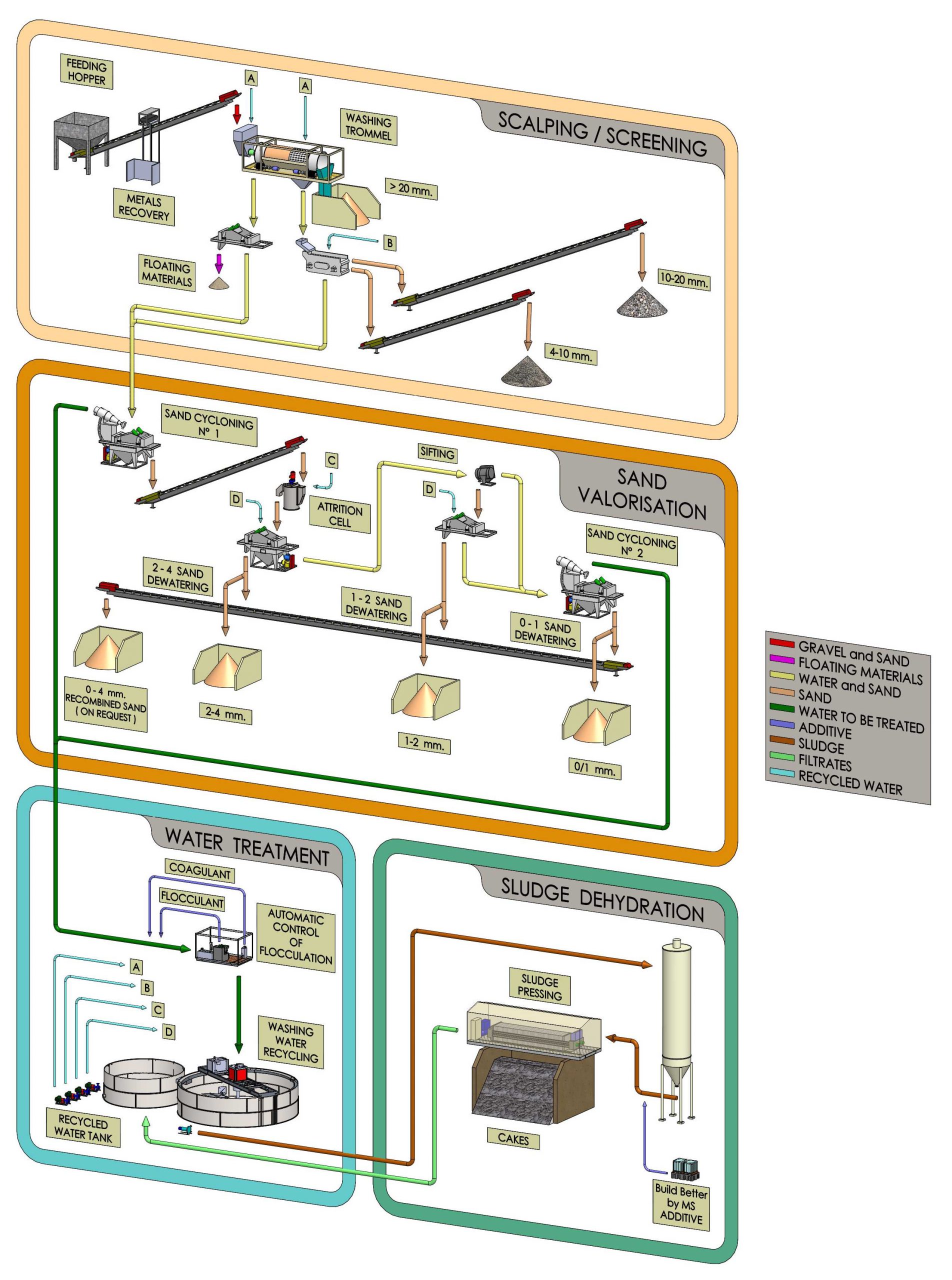

a global offer: Save Sand by MS

At the current time, quarry waste rock and excavated material from construction and public works sites are for the most part considered to be waste. However, this excavated material has one great asset: sand. This natural resource, which is used in concrete, is being used up faster and faster. But we still need it for new buildings. You might not believe it, but the waste you generate can become profitable! There are ways to make the most of it. Optimise your recycling and create a new source of income. Steer your waste management towards an approach that is responsible, sustainable and financially advantageous.

BUILD BETTER BY MS offers you its new range of SAVE SAND equipment to assist you throughout the porcess.

Our washing trommel, the MS TriForce : an innovative 3-in-1 solution !

- De-agglomerate and attrition of materials

- Scalping at 20mm

- Backflow system for the recovery of floats

The screen is directly set under the trommel in order to :

- avoid the transportation issue of materials that would be too

wet - Limit the ground surface area

- Reduce the cost with a compact installation

Your spoils, coming from various sources, may contain more or less sand, scrap metal, clay, plastic, concrete, fines, cardboard, polystyrene etc…

Despite the variation, you will produce consistent grain size and quality material. In order to meet your expectations, OPTIONAL steps are also available:

- Pre-screening: control and regulation of inputs granulometry

- Overband : separation of metallic elements

- Logwasher : removal of clays / light contamination.

- Attrition: advanced screening process for fine grain sizes

On Save Sand plant, you clarify the wastewater from the washing of materials, so that all the equipment involved in the process (screens, washers, wringers) can be supplied with high-quality, recycled water.

Have a look at Save Sand !

A complete platform for materials recycling and recovering

Discover the MS TRIFORCE

A innovative 3-in-1 solution : the TRIFORCE

A single, global offer covering the entire valorisation process of your products to be recycled!

Choose sustainable equipment to :

- transform your outgoing waste into added value

- preserve the environment by meeting today's challenges.

A global offer !

Make your orders easier and deal with one single service provider. Together with the best partners, we cover the entire recycling process for you.